Spot type

| Assure wafer quality |

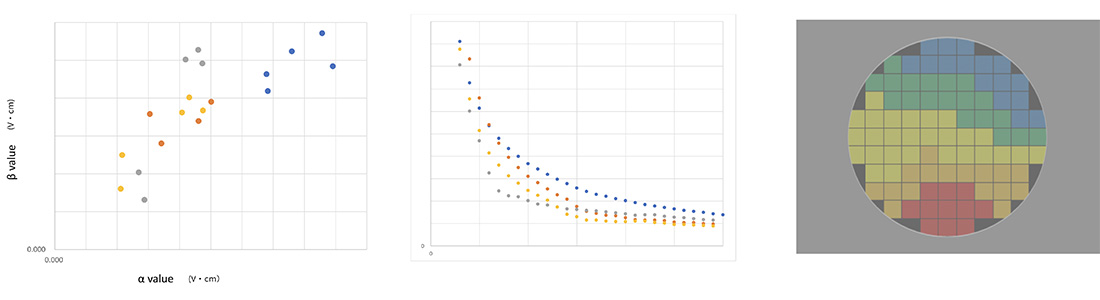

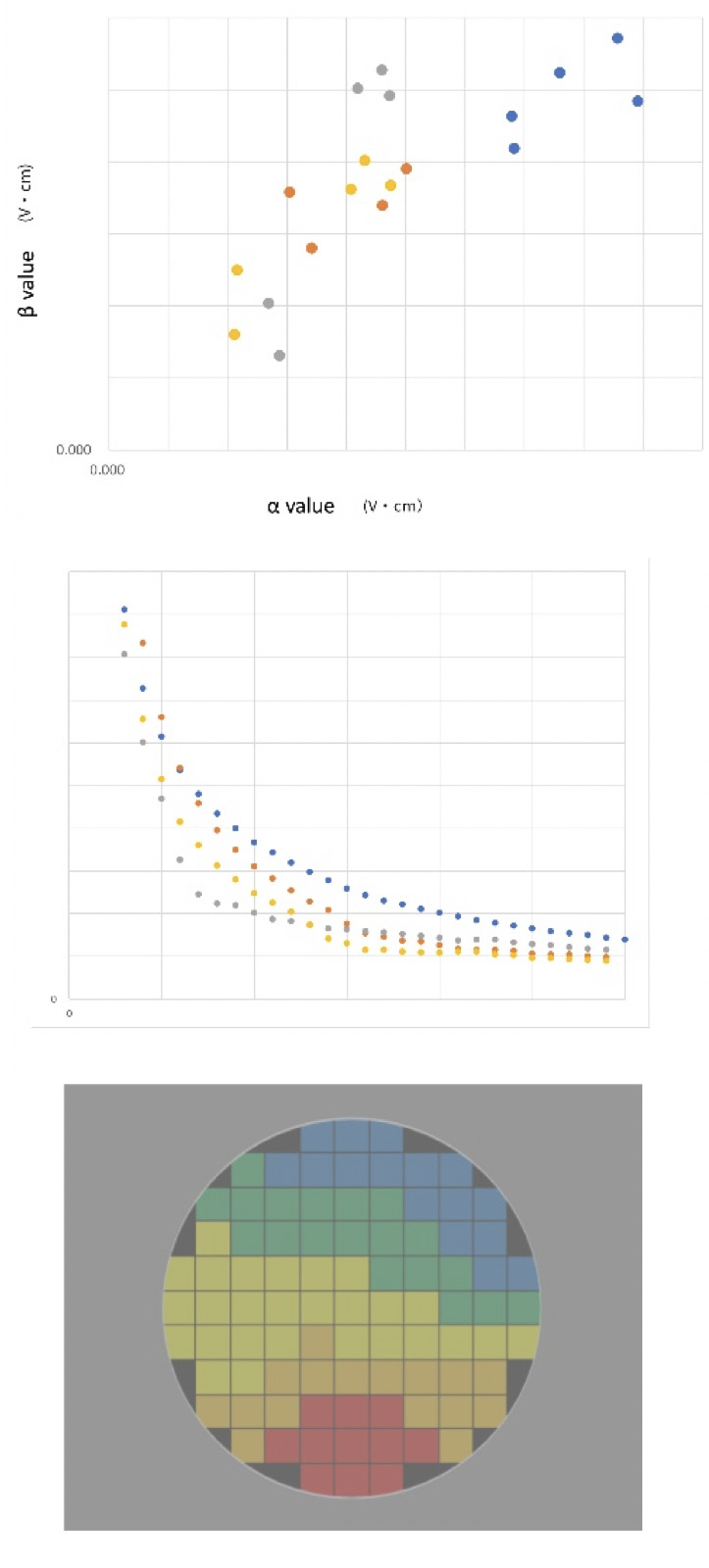

Measurement results reflecting defect density and dopant concentration.

Accurately measures surface and internal quality of wafers.

|

| Improving wafer development efficiency |

Quality evaluation immediately after wafer slicing or wafer polishing provides quality information feedback in a short cycle.

|

| Improving of defect rate |

Improve defect rate by early detection and elimination of defective wafers.

Ideal for selecting wafer suppliers. |

| Device Specification |

| ●Size |

W900 × D900 × H700 mm |

| ●Weight |

Approx.50 ㎏ |

| ●Power |

Single-phase AC 90 – 240 V |

| ●Operating environment |

Temperature and Humidity 25±5℃・≦85%RH |

| Measurement Performance |

| ●Measuring time |

10sec or less / point |

| ●Measuring method |

Probe contact type |

| ●Sample size |

Up to 12inch |

| ●Sample resistivity |

Up to 20.0 Ω・cm |

| ●Measuring object |

p/n type Monocrystal |

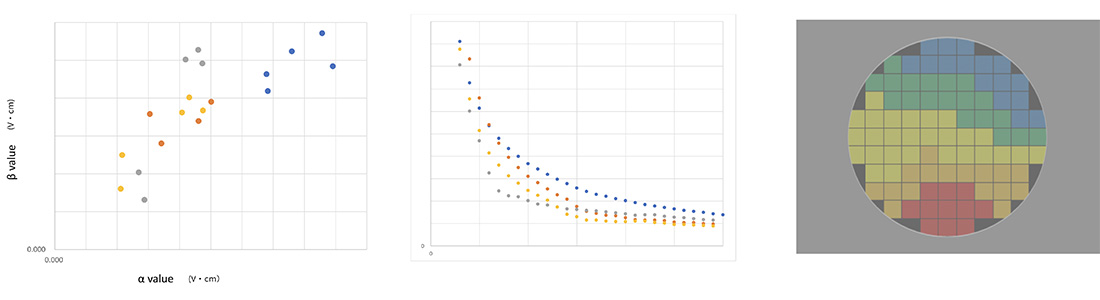

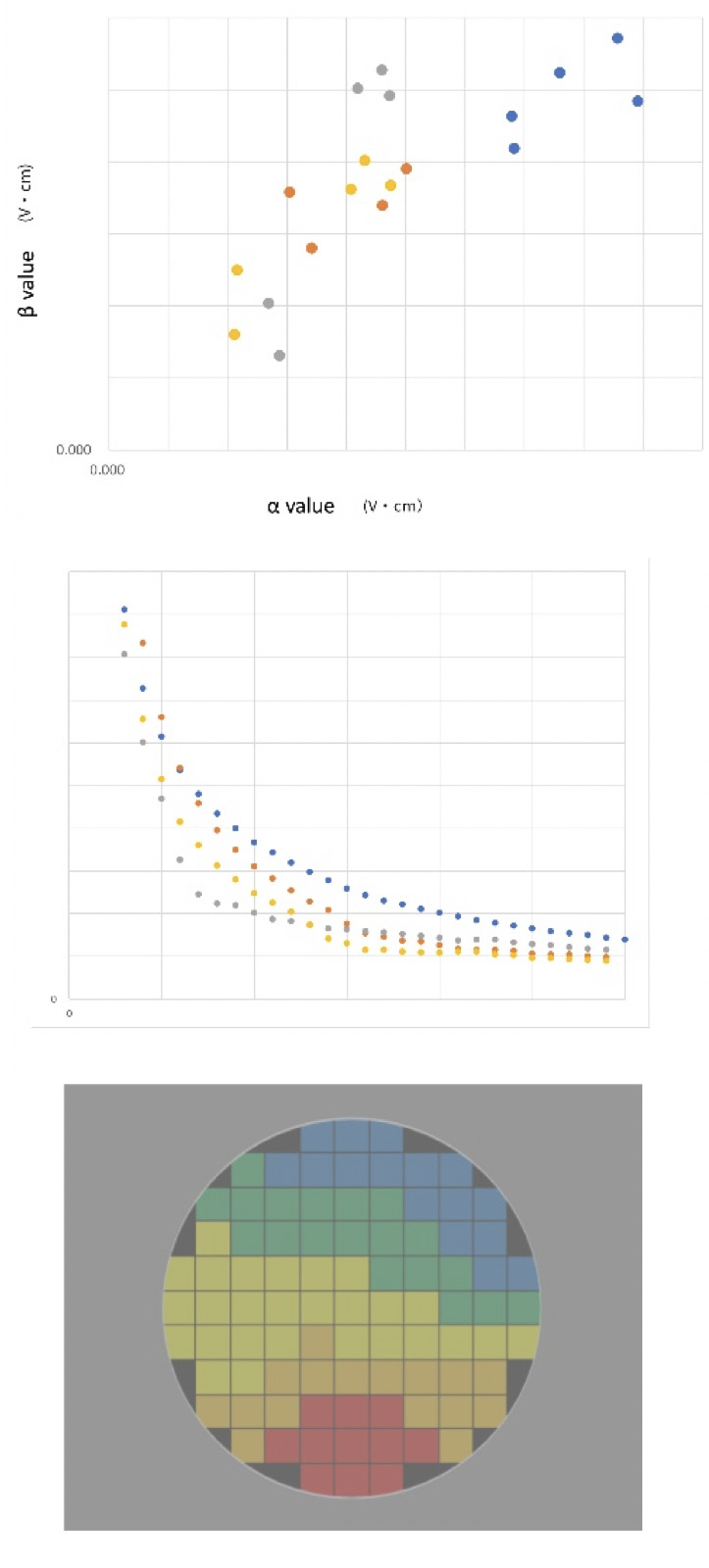

Measurement result (image)

In-line Type for Full Inspection

- Corresponding to full inspection by connecting to the mass production line.

- By customizing the number of wafers to be measured at the same time, inspection time can be shortened.

*build-to-order

| Device Specification |

| ●Size |

W2000 × D1500 × H1500 mm |

| ●Weight |

Approx. 500 ㎏ |

| ●Power |

Single-phase AC 100 – 230 V |

| ●Operating environment |

Temperature and Humidity 25±5℃・≦85%RH |

| Measurement Performance |

| ●Measuring time |

1sec / wafer |

| ●Measuring method |

Probe contact type |

| ●Sample size |

Up to 12inch |

| ●Sample resistivity |

Up to 20.0 Ω・cm |

| |

|